Aerospace PCB Assembly Precision in the Skies

In the world of aerospace, precision and reliability are non-negotiable. Whether it’s an aircraft, satellite, or spacecraft, the functionality and safety of aerospace systems depend on the meticulous assembly of Printed Circuit Boards (PCBs). In this article, we will explore the critical significance, unique challenges, and stringent requirements involved in aerospace PCB assembly.

1. The Critical Role of PCBs in Aerospace

Printed Circuit Boards (PCBs) are the central nervous system of aerospace systems. They provide the necessary electrical connections, data processing, and control functions that are essential for safe and efficient operation. Aerospace PCB assembly is not just about soldering components onto a board; it’s about ensuring that every connection is reliable and resilient, even in the harshest of environments.

2. Stringent Standards and Regulations

Aerospace PCB assembly adheres to some of the most stringent quality standards in any industry. Safety is paramount, and compliance with standards such as AS9100 and IPC-A-610 is mandatory. These standards ensure that every aspect of the assembly process, from component selection to soldering, meets the highest levels of quality and reliability.

3. Extreme Environmental Challenges

Aerospace systems operate in environments that are far from forgiving. From the extreme temperatures and pressures of outer space to the intense vibrations and stresses experienced during takeoff and landing, PCBs must be designed and assembled to withstand these conditions without failure.

4. Miniaturization and Component Density

Space is a precious commodity in aerospace design. Smaller, lighter components and PCBs are necessary to minimize weight and maximize efficiency. This demand for miniaturization requires precision in component placement and soldering, as well as advanced PCB manufacturing techniques.

5. Advanced Material Selection

The choice of PCB materials is critical in aerospace assembly. High-temperature laminates, such as polyimide, are often used to ensure that the PCB can withstand extreme temperatures. Additionally, materials must minimize outgassing, which can be problematic in vacuum environments.

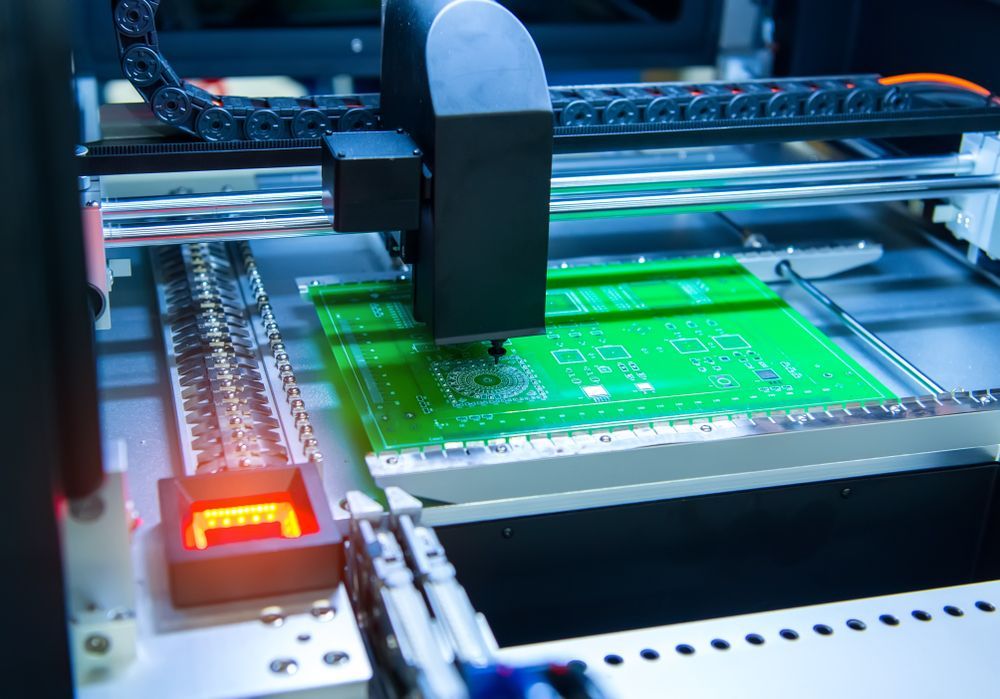

6. Automated Assembly for Precision

Aerospace PCB assembly relies heavily on automated manufacturing processes. Robotic pick-and-place machines ensure that components are Anzer precisely positioned, while automated soldering processes guarantee the reliability of connections. These automated systems are essential to maintain consistency and accuracy.

7. Quality Control and Testing

Rigorous testing and inspection procedures are integral to aerospace PCB assembly. X-ray inspection, functional testing, and thermal cycling tests are just a few examples of the measures taken to ensure the reliability of the assembled PCBs.

See more information at odidea.net

8. The Future of Aerospace PCB Assembly

The aerospace industry is continually evolving, with a growing focus on innovation. Advancements in materials, miniaturization techniques, and the integration of embedded components within PCBs are on the horizon, promising even more reliable and efficient aerospace systems.

Conclusion

In conclusion, aerospace PCB assembly is a critical aspect of aerospace technology. It demands unwavering precision, uncompromising reliability, and a commitment to innovation. As aerospace systems continue to advance, the role of PCBs will remain central, driving advancements that enable safer, more efficient, and more capable aircraft and spacecraft.