Why Elite Mold Services Are the Key to Superior Product Quality

In today’s highly competitive manufacturing landscape, producing superior quality products is non-negotiable. Whether you’re in the automotive, medical, electronics, or consumer goods industry, your product’s success begins long before it reaches consumers—it starts in the mold. Specifically, elite mold services have emerged as a crucial element in ensuring consistent product excellence. These top-tier mold services go beyond standard practices, offering advanced technology, precision engineering, and expert craftsmanship that collectively raise the bar for product quality.

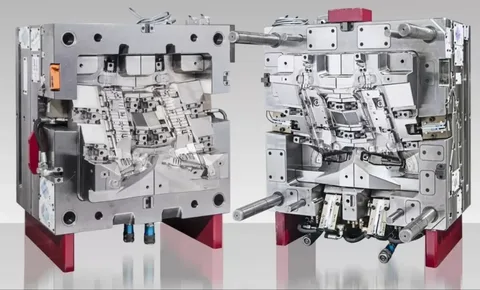

Elite mold services are not just about creating cavities for injection molding; they are about engineering excellence at every level. From the initial mold design to final production, every step is optimized for performance, reliability, and repeatability. These services ensure tight tolerances, minimal defects, and maximum efficiency, making them a key investment for manufacturers seeking to stand out in saturated markets.

The Precision Advantage of Elite Mold Services

One of the most prominent benefits of elite mold services is the unparalleled precision they offer. Precision in mold creation is critical because it directly impacts the final dimensions, functionality, and aesthetics of the molded part. Elite mold providers utilize state-of-the-art CNC machines, EDM (Electrical Discharge Machining), and 3D measurement systems to ensure micron-level accuracy. Such precise engineering ensures consistent part quality and virtually eliminates the risk of defects like warping, flash, or misalignment.

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

This level of accuracy is especially vital for industries like aerospace and medical devices, where even the slightest variation can compromise safety or functionality. Elite mold services ensure every detail is perfect—from wall thickness to surface finish—resulting in a product that not only looks better but performs better. When precision is baked into the mold, manufacturers can produce thousands or even millions of units without worrying about inconsistencies or costly reworks.

Advanced Materials and Technologies

Elite mold services also stand apart due to their use of advanced materials and cutting-edge technologies. High-performance steel, beryllium-copper alloys, and ceramic inserts are commonly used in elite mold manufacturing to ensure durability, thermal conductivity, and resistance to wear. These materials increase the lifespan of the mold while maintaining consistent quality over long production cycles. Unlike standard molds, elite molds can withstand higher injection pressures and temperatures without degrading, leading to more reliable product output.

Additionally, elite mold manufacturers often leverage modern technologies such as conformal cooling, hot runner systems, and simulation software. Conformal cooling allows for faster, more uniform cooling cycles, reducing production time and improving part quality. Meanwhile, hot runner systems eliminate material waste and improve cycle time. With simulation tools, mold flow analysis can predict and correct potential issues before the first mold is cut. These innovations reduce errors, improve efficiency, and help create products that are consistently superior in quality.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

Expertise and Collaboration in Mold Design

The value of elite mold services also lies in the level of expertise and collaborative approach they bring to mold design. Elite mold providers employ seasoned engineers who have years of experience designing molds for complex geometries, tight tolerances, and specialized applications. Their in-depth knowledge ensures that the mold is not just functional but optimized for manufacturability, longevity, and cost-effectiveness. This results in lower scrap rates, fewer production delays, and higher overall profitability.

Moreover, elite mold makers typically work closely with their clients throughout the design and development process. From design reviews to material selection and mold testing, the process is highly interactive and transparent. This collaborative partnership ensures that the final product meets the client’s exact specifications and industry standards. Manufacturers benefit from expert insights that can lead to design improvements, cost savings, and better end-user experiences. This consultative approach is a hallmark of elite mold services and a key reason behind their ability to deliver top-tier results.

Quality Control and Regulatory Compliance

Another critical aspect of elite mold services is their rigorous approach to quality control and compliance. Elite mold providers implement strict quality assurance protocols that include in-process inspections, post-production audits, and detailed documentation. This ensures that every mold and part produced meets the highest standards of quality and performance. By identifying and addressing potential issues early in the process, they prevent costly mistakes and downtime later on.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

In addition to quality, elite mold services ensure full compliance with regulatory standards across various industries. Whether it’s ISO 13485 for medical devices, AS9100 for aerospace, or IATF 16949 for automotive, elite mold manufacturers are well-versed in these standards and incorporate them into their production processes. This guarantees that the parts produced not only meet design specifications but also fulfill all necessary legal and safety requirements. For manufacturers, this level of assurance is invaluable—it means fewer recalls, reduced liability, and greater trust among customers and stakeholders.

Competitive Advantage and Long-Term ROI

Investing in elite mold services isn’t just about producing better parts—it’s about gaining a sustainable competitive edge. When companies deliver consistently high-quality products, they enhance their brand reputation, increase customer loyalty, and capture greater market share. Elite molds enable faster cycle times, higher output, and fewer defects, all of which contribute to a more efficient and profitable operation. In essence, elite mold services don’t just improve quality—they also drive business success.

While elite molds may have a higher upfront cost compared to standard molds, the long-term return on investment (ROI) is significantly higher. These molds are built to last longer, perform better, and require less maintenance, which reduces overall production costs. They also allow manufacturers to scale production quickly without compromising quality. Over time, the savings in waste reduction, labor, and time outweigh the initial expenses. For companies looking to grow and dominate their markets, elite mold services are not a luxury—they are a strategic necessity.

Conclusion

Elite mold services are the foundation upon which superior product quality is built. From unmatched precision and advanced technology to expert collaboration, strict quality control, and strategic ROI, these services offer a comprehensive solution to modern manufacturing challenges. In a world where consumers expect nothing less than perfection, elite mold solutions ensure that manufacturers can meet—and exceed—those expectations.