Why Are Coiled Springs Used in Mechanical Applications?

A coiled spring is one of the most fundamental components in various mechanical applications. Whether in automobiles, industrial machinery, medical devices, or household appliances, coiled springs play a vital role in storing and releasing energy efficiently. Their design allows them to absorb shock, maintain tension, and return to their original shape after compression or extension. The unique properties of coiled springs make them indispensable in engineering and mechanical industries.

How Do Coiled Springs Function in Different Systems?

The fundamental purpose of a coiled spring is to exert force and absorb energy. When force is applied to a spring, it either compresses, extends, or twists depending on its type. Once the force is removed, the stored energy enables the spring to return to its initial form. This ability ensures smooth mechanical operations in systems that require controlled motion, load management, or vibration absorption.

Coiled springs are widely used in:

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

- Automotive suspensions – To absorb road shocks and ensure vehicle stability.

- Industrial machinery – To maintain tension in moving parts.

- Medical devices – To provide precision in surgical and diagnostic tools.

- Aerospace components – To ensure durability under high-stress conditions.

Why Is Determining Spring Rate Important for Performance?

Determining spring rate is crucial for ensuring the proper function of a coiled spring in mechanical applications. Spring rate, measured in force per unit of deflection (typically pounds per inch or Newtons per millimeter), defines how much load a spring can handle before it deforms beyond its elastic limit.

Factors affecting spring rate include:

- Wire diameter – Thicker wire results in a stiffer spring.

- Coil diameter – A larger coil diameter results in a softer spring.

- Number of active coils – More coils reduce stiffness, while fewer coils increase it.

- Material type – Different materials offer varied elasticity and resistance.

Choosing the correct spring rate ensures that the coiled spring operates effectively without failure, enhancing the reliability of the entire mechanical system.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

How Are Coiled Springs Custom-Designed for Specific Applications?

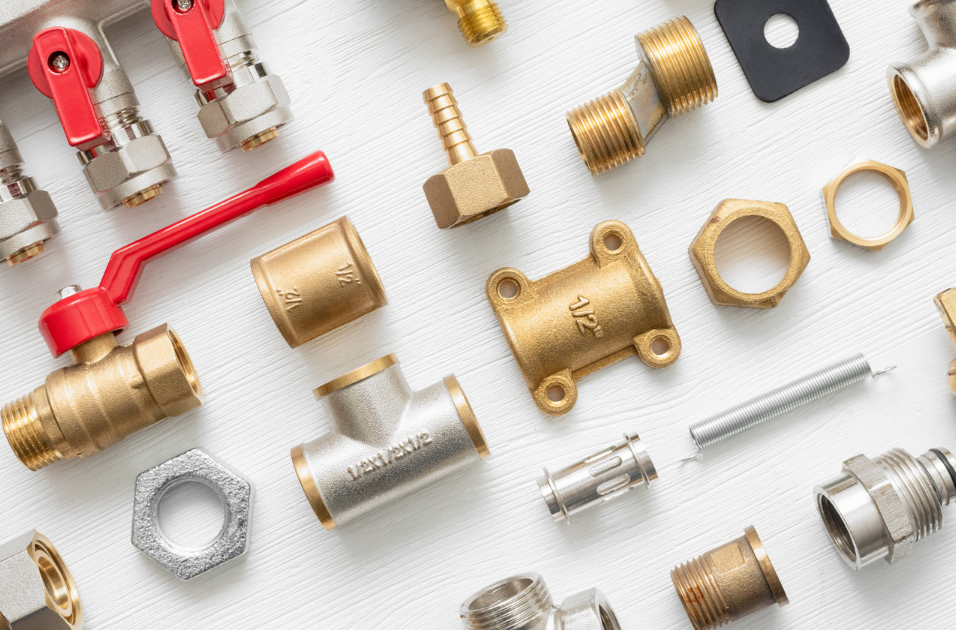

Manufacturers like Acxess Spring specialize in custom-designed coiled springs tailored to meet specific mechanical requirements. The design process includes:

- Load calculations – Determining the amount of force the spring needs to support.

- Material selection – Choosing the right metal alloy for durability and elasticity.

- Coil configuration – Adjusting diameter, pitch, and the number of turns for precise performance.

- Surface treatment – Applying coatings for corrosion resistance and longevity.

By optimizing these factors, engineers can ensure that a coiled spring performs efficiently under intended operational conditions.

What Are the Different Types of Coiled Springs Used in Engineering?

Mechanical applications require different types of coiled springs, each serving a unique function. The most common types include:

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Compression Springs

Compression springs resist compressive forces and return to their original shape when the load is removed. They are widely used in automotive suspensions, industrial presses, and electronic devices.

Extension Springs

Extension springs operate by resisting stretching forces. They are commonly found in garage doors, trampolines, and mechanical levers.

Torsion Springs

Torsion springs store rotational energy and exert torque when twisted. Applications include clothespins, door hinges, and automobile suspensions.

How Does Acxess Spring Ensure High-Quality Coiled Springs?

As a leading manufacturer, Acxess Spring ensures that every coiled spring meets industry standards through rigorous quality control processes. By using advanced testing equipment, engineers verify load capacity, elasticity, and material integrity. With precision manufacturing and custom design options, Acxess Spring continues to be a trusted supplier for industries requiring durable and high-performance springs.

Conclusion

Coiled springs are indispensable in mechanical applications due to their ability to store energy, absorb shock, and provide stability. Determining spring rate is a critical step in designing an efficient mechanical system, ensuring optimal performance and longevity. Whether for automotive, industrial, or aerospace applications, high-quality coiled springs from trusted manufacturers like Acxess Spring guarantee reliable operation and durability in diverse environments.