What Should You Know Before Buying Length Stop Measuring Systems in 2025?

When it comes to perfection and effectiveness in ultramodern manufacturing or woodworking, Length Stop Measuring Systems are among the most dependable tools available at the moment. In 2025, technology has advanced in ways that make these systems more accurate, protean, and stoner-friendly. Still, before investing in one, it’s essential to understand crucial considerations that can impact performance, cost- effectiveness, and long- term usability. The ensuing sections will guide you through the most important aspects to consider when opting a measuring system for your operation.

Understanding the Part of Length Stop Measuring Systems

The first step before copping is understanding what the system does and how it functions in colorful settings. These systems are designed to control the positioning of material with perfection, helping drivers achieve harmonious cuts, reduced waste, and better workflow. In artificial and factory surroundings where delicacy is critical, they reduce crimes and increase productivity. Knowing their purpose ensures that buyers align the system’s capabilities with their specific design requirements.

Assessing Accuracy and Precision Situations

delicacy remains one of the most critical factors when choosing a measuring system. In 2025, numerous systems incorporate digital technology, advanced detectors, and automated adaptations that deliver advanced perfection than ever before. Still, delicacy can vary depending on the brand, model, and type of system. Before copping , it’s necessary to estimate whether the system’s perfection meets the conditions of your accoutrements , whether you’re working with wood, essence, or compound products. The advanced the perfection, the further harmonious the results, which directly influences the quality of finished products.

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

Considering Robotization Features

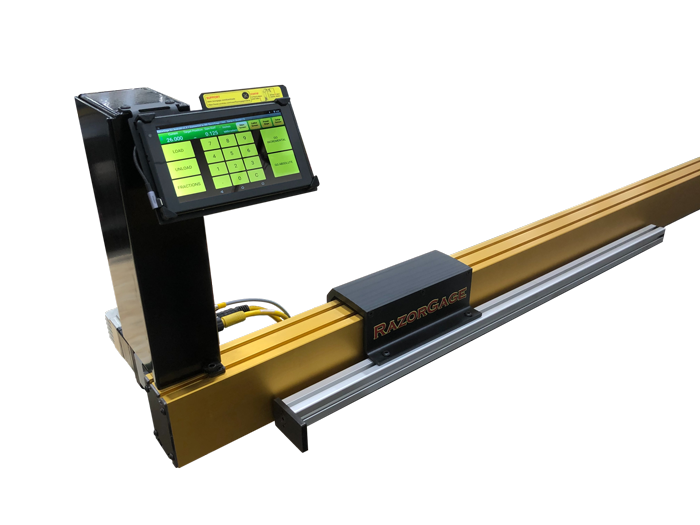

Robotization is shaping the future of manufacturing, and Length Stop Measuring Systems are no exception. Numerous systems now come with programmable stops, motorized adaptations, and touchscreen interfaces. These advancements help drivers save time by minimizing homemade setup and reducing repetitious tasks. Buyers should assess the extent of robotization they bear grounded on the scale of the product. While lower shops may prefersemi-automated results, larger operations frequently profit from completely automated systems that can handle nonstop products without homemade intervention.

Comity with Being Machinery

Another pivotal factor is icing comity between the measuring system and being saws, drills, or cutting outfit. Not every system integrates seamlessly with all machines, which can lead to challenges during installation. comity ensures smooth operation and reduces the need for variations or fresh accessories. In 2025, numerous systems offer modular designs, but it remains essential to corroborate whether the system supports the outfit you formerly used. Proper alignment between the system and ministry can help avoid time-out and gratuitous costs.

Continuity and Figure Quality

continuity directly affects the life of a measuring system. Given the heavy- duty surroundings where these systems are frequently used, accoutrements similar as hardened sword, artificial- grade aluminum, and corroborated factors play a crucial part in extending lifetime. A system designed for adaptability can repel nonstop use and repel wear and tear from repetitious movements. Buyers should also consider whether the system has protection features against dust, debris, or climate, as these factors frequently compromise performance over time.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

Assessing Ease of Use and Operator Training

A system may be technologically advanced, but if it’s delicate for drivers to use, it may produce inefficiencies rather than working for them. Ease of use is an important factor in opting the right result. Systems with clear digital displays, intuitive controls, and straightforward estimation processes make it easier for staff to acclimatize snappily. In 2025, training modules and indeed stoked reality guidance tools are getting more common, reducing the literacy wind. Before copping , it’s wise to assess how important time and trouble will be needed for training drivers on the system.

Assessing Conservation and Service Conditions

Every measuring system requires some position of conservation, but the frequency and complexity of these conditions can vary. Systems designed with smaller moving corridors or tone- slicking mechanisms frequently bear lower keep, while others may need regular adaptations. Buyers should probe what kind of conservation schedule is necessary and whether relief corridors are fluently available. Availability to specialized support and stoner primers can also impact how effectively a system is maintained. In the long run, ease of conservation can make a substantial difference in cost and time-out.

Assaying Software Integration Capabilities

In digital geography, software integration is just as important as mechanical performance. ultramodern systems frequently connect with computer- backed design( CAD) programs, product planning tools, and data shadowing software. This integration allows drivers to streamline workflows, dissect product effectiveness, and reduce mortal error. When opting a system, it’s important to corroborate whether it can integrate with your current software platforms. In 2025, pall connectivity and real- time monitoring are decreasingly common features, furnishing better perceptivity into product processes.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Cost Versus Long- Term Value

Price is always a major consideration, but it should n’t be the only factor. Rather than fastening solely on the outspoken cost, buyers should estimate the long- term value of a system. A lower- cost option may save plutocrats originally but could lead to advanced conservation charges, lower perfection, or further frequent reserves. Again, a more advanced system may offer better continuity, robotization, and effectiveness that eventually save costs over time. The key is to balance budget constraints with long- term functional pretensions.

Preparing for Unborn Scalability

Eventually, scalability is an aspect frequently overlooked when copping measuring systems. As businesses grow, product requirements may change, and outfit should be suitable to keep pace. Scalable systems that allow upgrades, fresh features, or integration with new ministry ensure that investments remain precious for times to come. Buyers in 2025 should consider not only their current conditions but also implicit expansion. A system that can acclimatize to unborn demands provides lesser inflexibility and reduces the need for expensive reserves.

Conclusion Moving Forward with Confidence

Before copping any measuring result in 2025, careful consideration of delicacy, comity, continuity, robotization, and software integration is essential. Each factor contributes to how efficiently a system will perform and how well it’ll support long- term pretensions. Buyers should take time to estimate both current requirements and unborn scalability, icing that the system remains applicable as technology and product conditions evolve. By understanding these rudiments, one can make a well- informed decision that not only enhances productivity but also contributes to Optimizing saws for the future.