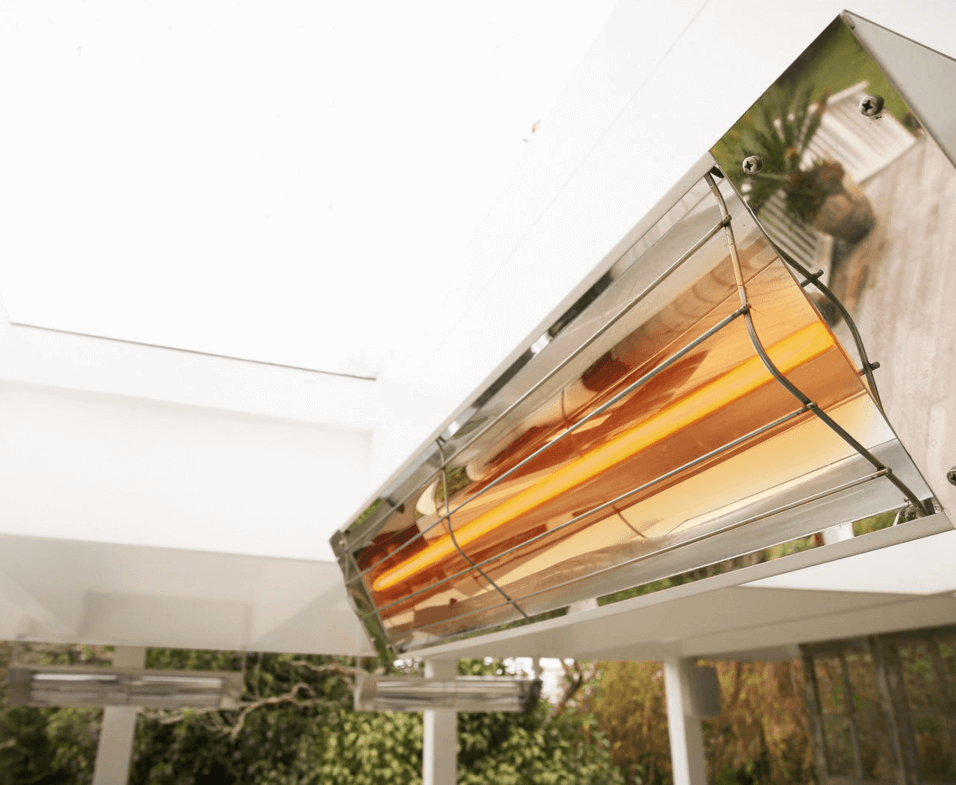

In various industrial applications, maintaining the right temperature is crucial for efficiency, safety, and product quality. Pipeline electric heater emerged as a sustainable solution, providing effective temperature control while minimizing environmental impact. In this blog, we will explore the benefits, applications, and key features of pipeline electric heaters, highlighting why they are a preferred choice in modern industries.

Understanding Pipeline Electric Heaters

Pipeline electric heaters are designed to heat fluids as they flow through pipelines. These heaters utilize electric heating elements to transfer heat directly to the fluid, ensuring that it maintains its desired temperature. Unlike traditional heating methods, which may rely on fossil fuels or steam, electric heaters offer a more environmentally friendly alternative.

Key Advantages of Pipeline Electric Heaters

- Energy Efficiency: One of the primary benefits of pipeline electric heaters is their energy efficiency. They convert electrical energy directly into heat with minimal losses, making them highly effective in maintaining consistent temperatures. This efficiency not only reduces operational costs but also lowers energy consumption, making them a sustainable option.

- Precise Temperature Control: Pipeline electric heaters provide precise temperature control, which is essential in many industrial processes. With advanced temperature regulation technology, these heaters can be programmed to maintain specific temperature ranges, ensuring optimal conditions for the fluids being transported.

- Reduced Emissions: Unlike traditional heating methods that may emit greenhouse gases, electric heaters produce no direct emissions during operation. This contributes to a cleaner environment and aligns with sustainability goals for industries seeking to reduce their carbon footprint.

- Versatility: Pipeline electric heaters can be used in various applications, including oil and gas, chemical processing, food and beverage, and water treatment. Their versatility allows them to accommodate different fluids and heating requirements, making them suitable for a wide range of industries.

- Minimal Maintenance: Compared to other heating methods, electric heaters typically require less maintenance. They have fewer moving parts and do not rely on combustion processes, reducing wear and tear over time. This results in lower maintenance costs and less downtime for repairs.

- Safety Features: Modern pipeline electric heaters come equipped with advanced safety features, including temperature sensors, automatic shut-off systems, and over-temperature protection. These features enhance safety and reduce the risk of accidents, making them a reliable choice for industrial applications.

Applications of Pipeline Electric Heaters

Pipeline electric heaters are utilized across various industries, including:

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

- Oil and Gas: In the oil and gas sector, maintaining fluid temperatures is crucial for ensuring smooth transportation and preventing wax buildup in pipelines. Electric heaters help keep crude oil and other hydrocarbons at optimal temperatures, facilitating efficient flow.

- Chemical Processing: In chemical manufacturing, precise temperature control is essential for reactions and processes. Pipeline electric heaters ensure that reactants remain within the desired temperature range, enhancing product quality and consistency.

- Food and Beverage: In the food and beverage industry, maintaining proper temperatures during processing and transportation is critical for safety and quality. Electric heaters help ensure that ingredients and products are kept at the right temperatures throughout the supply chain.

- Water Treatment: In water treatment facilities, electric heaters are used to maintain optimal temperatures for various processes, including disinfection and chemical dosing. This ensures effective treatment and compliance with safety standards.

Selecting the Right Pipeline Electric Heater

When choosing a pipeline electric heater, several factors should be considered to ensure you select the right solution for your specific needs:

- Fluid Type: Different fluids have different thermal properties. Ensure that the heater you choose is compatible with the type of fluid being transported, whether it’s oil, water, or chemicals.

- Temperature Requirements: Determine the temperature range required for your application. This will help you select a heater with the appropriate heating capacity and control features.

- Installation Requirements: Consider the space available for installation and any specific mounting or configuration requirements. Some heaters may require additional insulation or support structures.

- Power Supply: Check the available power supply at your facility. Ensure that the heater’s power requirements match your electrical system’s capacity to avoid complications during installation.

- Safety Standards: Look for heaters that comply with relevant safety and industry standards. This ensures that the equipment is designed to operate safely within your specific industry context.

Conclusion

Pipeline electric heaters represent a sustainable solution for effective temperature control across various industries. Their energy efficiency, precise temperature regulation, reduced emissions, and versatility make them an excellent choice for maintaining optimal conditions in fluid transportation. As industries continue to prioritize sustainability and efficiency, pipeline electric heaters will play an increasingly important role in modern operations.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.