Maximizing Lignite Potential: Briquetting Technology

Lignite also known as brown coal is a type of coal with a high level of moisture content and a relatively low percentage of carbon. Although as a lower grade of coal, it is far less efficient when burned in its crude form due to the great amount of smoke output and low heat yield. Despite this, there is a way to bring lignite’s efficiency closer to that of the other three types of coal and also make it more friendly to the environment by a process known as briquetting.

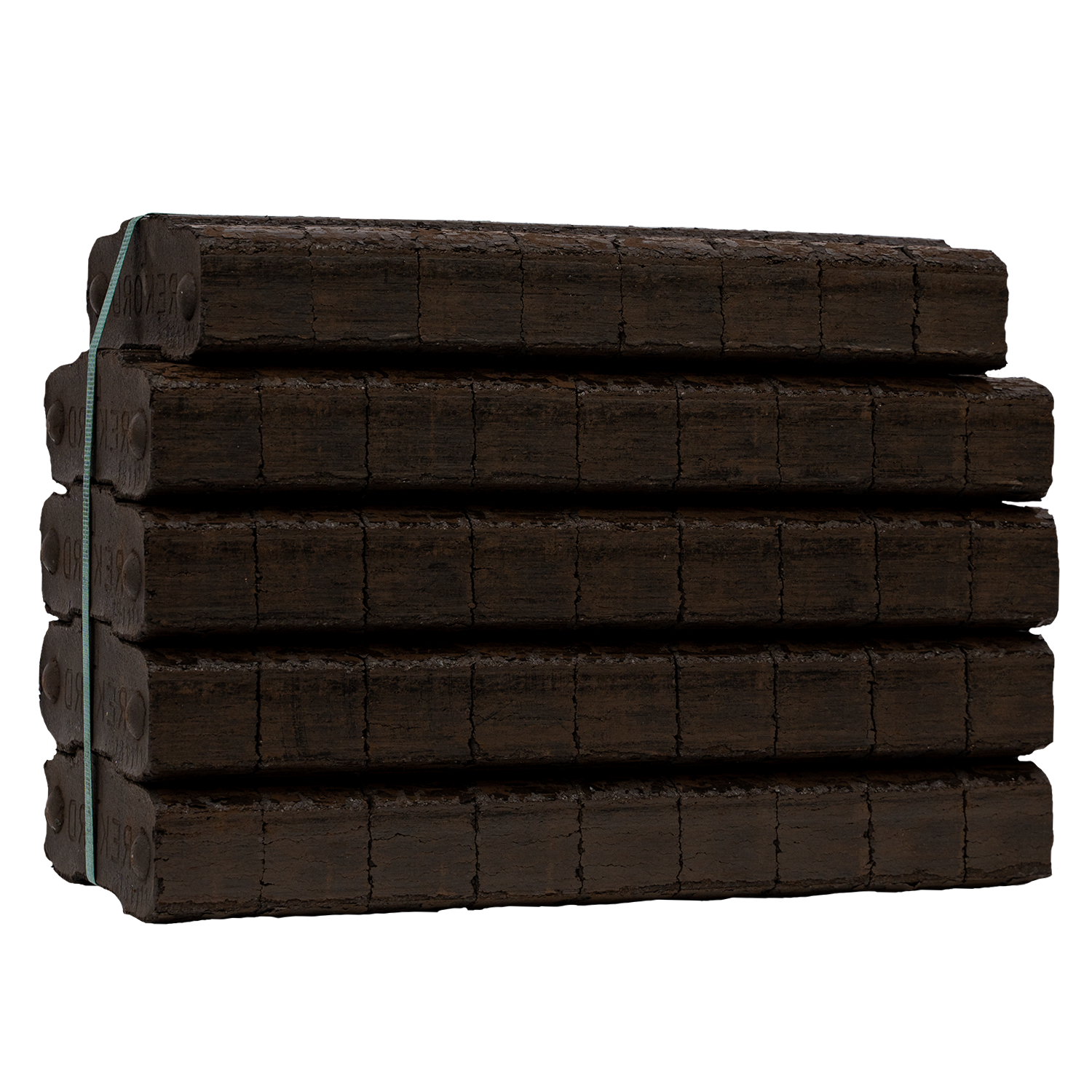

This transformation has received quite much attention, especially in countries such as Austria where producer companies of Brown coal briquettes aim at enhancing the utility of lignite. When lignite is briquetted into solid compacted balls it becomes a very useful fuel that can be used in industries and homes.

Understanding Lignite Briquetting

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

Briquetting is a technique of converting the low density and low-combustion value lignite into small densified fuel briquettes through a high-pressure compaction. In improving the size and moisture content, the briquetting technology increases the efficiency of lignite and decreases emissions, thus becoming a cleaner fuel. The briquettes posed fewer challenges in terms of storage, handling, and use compared to the raw lignite as the latter disintegrates and loses energy.

Lignite available today can be metamorphosed into energy-dense solid nuggets, known as Brown coal briquettes which are versatile and serve both industrial and domestic purposes. Apart from enhancing the efficiency of lignite, this technology assists producer companies of Brown coal briquettes from Austria and other world regions to realize the commercial value of the fuel.

The Briquetting Process

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

The briquette process is quite a simple process; however, the necessary equipment for the purpose is a bit complex. It involves several key steps:

- Drying the Lignite: Lignite is considered to be a very moisture-containing type of coal. To get a good stable efficient briquette the lignite has to be dehydrated in a way that removes moisture in the process. This is usually achieved by heating the lignite to the right moisture content The phenolic hydroxyl groups which are also present in the lignite structure give specific characteristics to the coal and are usually analyzed using infrared spectroscopy.

- Grinding: After drying, the lignite is comminuted to finer particle size. Grinding enhances the quality of the material and also enhances the compactness of the same material for easy shaping during the briquetting exercise.

- Compressing: The dried and powdered lignite is then conveyed forward to a briquette press machine which forms the particles into briquettes by exerting very high pressure. When the lignite particles are compressed heat is produced which makes it possible to induce particles without the use of binders.

- Cooling and Packaging: These briquettes are then cooled, to enable them to get more rigid, as well as be shippable. When the Brown coal briquettes are cool enough to reach room temperature, they are then bagged and palletized for storage or shipment.

Looking at the focus of briquetting, this transforms lignite from a low-efficiency raw fuel into a stable, compact and high-efficiency fuel. This change is relevant to lignite briquette producer companies in Austria as well as areas with the availability of lignite resources.

The Role of Brown coal briquettes in the Energy Industry

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Another method of utilization of this coal is in industries as, domestic purposes, and in the production of electrical power in thermal power stations. They are applicable where there is a low possibility of accessing natural gas or other fuel products and or where fuel is too costly. In Europe especially Austria, Brown coal briquettes play a significant role and this report evaluates options to improve this resource.

Austrian producer companies in the Brown coal briquettes industry aim to deliver these products to the national and global markets. The application of Brown coal briquettes to residential heating presents itself from the fuel’s efficiency, reliability, and lower emission than raw lignite or other solid fuels. More and more households in Austria intend to use Brown coal briquettes as a heat source during the cold season being more efficient and ecologically friendly.

Brown coal briquettes Producer company in Austria through kilns, boilers, and furnaces. The business that involves processes that need to have a steady supply of heat benefits from the high heat output and slow and steady burning of the Brown coal briquettes.