HMI Integration with PLCs

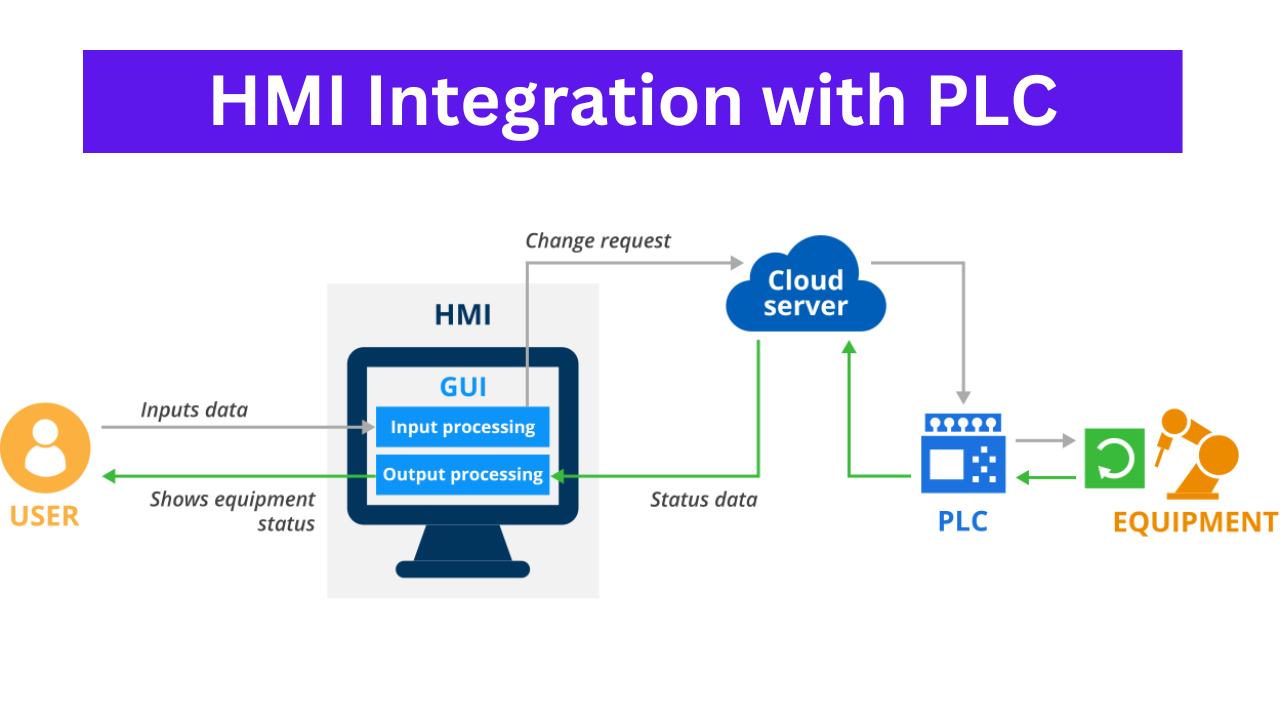

An essential component of industrial automation is the integration of PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces). HMI offers operators a graphical user interface for monitoring and managing a PLC-based control system.

An HMI (Human-Machine Interface) is a specific kind of equipment that creates a graphical interface between a control system and an operator. A PLC (Programmable Logic Controller), on the other hand, is a class of industrial computer used to automate control procedures in manufacturing and other sectors.

When these two devices are combined, it gives operators a strong tool for real-time monitoring and control of a PLC-based control system. The HMI device can display a variety of data from the PLC, including process variables, alarms, events, and historical trends.

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

Based on the program logic, the PLC reads data from input devices like sensors and operates output devices like motors, valves, and solenoids. The operator and the PLC are connected through the HMI. Through the HMI, the operator can issue commands to the PLC, which the PLC then processes to operate the output devices.

The HMI device may be a standalone unit connected to the PLC by Ethernet/IP or serial communication, or it may be a touchscreen panel installed on a machine. Modbus, OPC, or Ethernet/IP are just a few of the protocols that can be used to connect the PLC and HMI.

Benefits of using HMI with PLCs

Real-time monitoring and control:

Operators can monitor and manage the PLC-based control system in real-time thanks to the HMI, which enables real-time data visualization. Rapid issue detection and resolution are made possible by doing this, which boosts productivity and efficiency.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

Enhanced data visualization

Operators can more easily grasp and comprehend the system data since the HMI presents the data from the PLC in a graphical style. This improves the operator’s capacity to recognize trends and patterns and make informed judgments.

Improved system performance:

Operator interaction with the PLC-based control system is made simple and rapid by the HMI, which offers a user-friendly interface. As a result, system efficiency is increased, and downtime is decreased.

Increased system flexibility

The HMI provides a flexible interface that can be customized to meet the needs of different industrial automation systems. The HMI can be configured to display specific data, alerts, and messages, making it easy to integrate into a variety of control systems.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Remote access and monitoring

The HMI allows for remote access and monitoring of the PLC-based control system, providing operators with the ability to view and control the system from a remote location. This feature helps to reduce the need for on-site personnel and can lead to cost savings.

Better decision-making

The HMI gives operators the information and resources they need to make wise decisions, which improves system performance and boosts productivity. Real-time data, historical patterns, and alerts provided by the HMI make it easier to see potential problems before they get out of hand.

Allen Bradley MicroLogix 1400 PLC

Types of HMI used with PLCs:-

Touchscreen HMIs:

The most popular HMIs in industrial automation are touchscreen HMIs. The touchscreen interface on these devices enables users to communicate with the PLC-based control system. Data can be shown on touchscreen HMIs in a variety of formats, including graphs, charts, and tables, making it simpler for operators to understand the information.

Panel PC HMIs:-

Panel PC HMIs are comparable to touchscreen HMIs, but they additionally have a built-in computer. This makes it possible to use more complex features and computing power, such as executing software applications. Applications requiring a lot of computational power frequently use panel PC HMIs.

Portable HMIs:

Operators can monitor and manage the PLC-based control system using portable HMIs from any location on the production floor. These tools are especially helpful in situations like maintenance and troubleshooting where mobility is crucial.

Industrial PCs

Operators can monitor and manage the PLC-based control system using portable HMIs from any location on the production floor. These tools are especially helpful in situations like maintenance and troubleshooting where mobility is crucial.

With the adoption of new technologies like artificial intelligence, cloud-based computing, edge computing, wireless technology, advanced data visualization techniques, and increased cybersecurity measures, it is expected that the integration of HMI and PLCs will continue to develop. These developments will result in more sophisticated, adaptable, and safe control systems that can boost industrial automation’s effectiveness and productivity.