Why Onsite Balancing Engineering Solutions Are a Game-Changer

Turbochargers are essential parts of contemporary engines as they are known to increase performance and efficiency. Onsite balancing engineering solutions now emerge as a revolutionary tactic. For sectors that depend on turbochargers, these services provide unmatched advantages by removing imbalances and reducing downtime.

The Importance of Balancing in Turbochargers

Balancing is a critical process in the maintenance of turbochargers. Even minor imbalances in a turbocharger’s rotating assembly can lead to:

- Increased wear and tear of bearings and seals.

- Reduced efficiency and performance over time.

- Potential for catastrophic failures if left unaddressed.

Addressing these issues promptly is essential, and onsite balancing engineering solutions provide a direct answer by tackling the problem at its source.

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

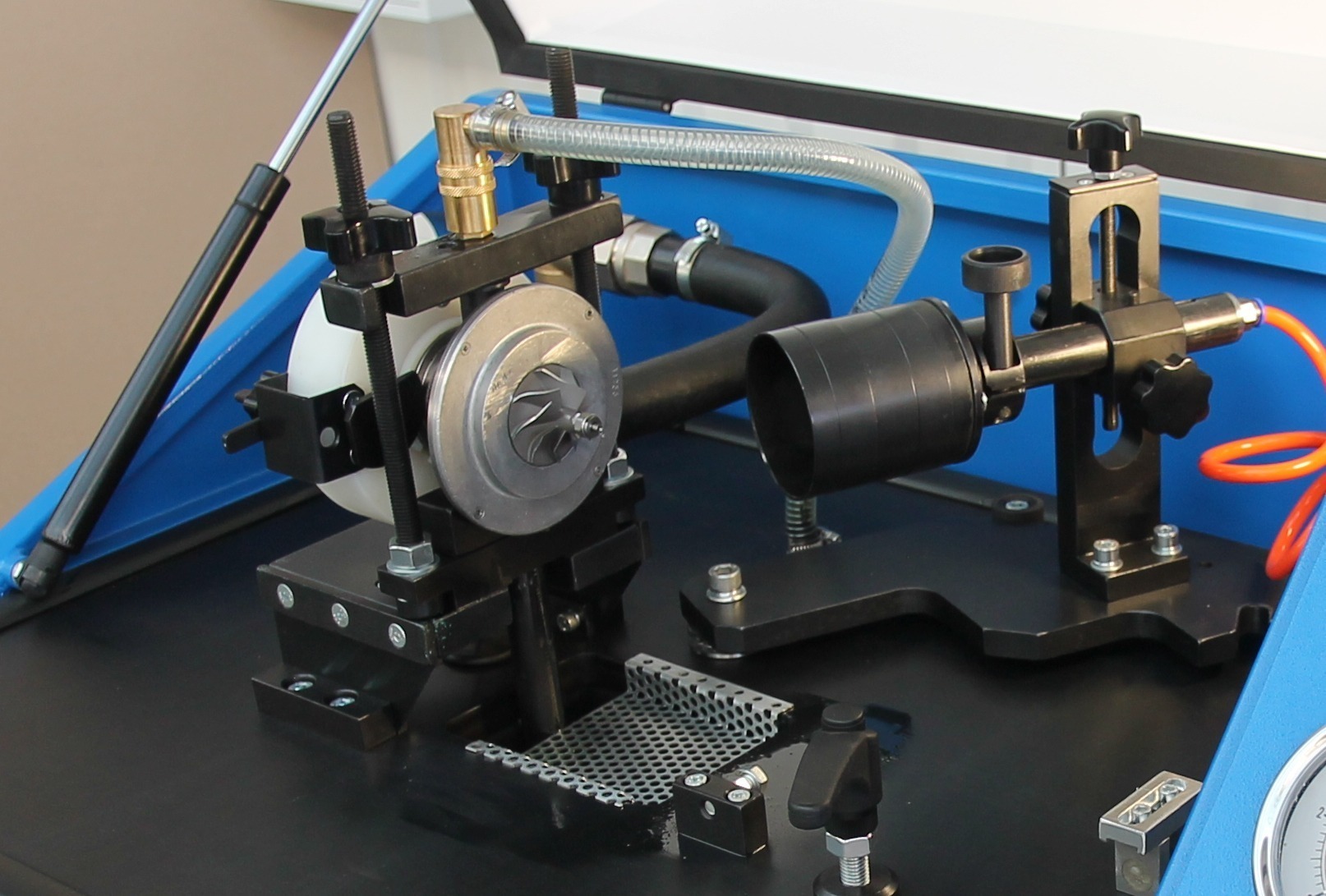

What Are Onsite Balancing Engineering Solutions?

Onsite balancing involves correcting the imbalance of rotating equipment directly at the location of operation. In contrast to conventional techniques that necessitate disassembly and transportation to offsite facilities, onsite solutions are implemented in real-time with the least amount of operational disruption.

Key Features of Onsite Balancing Solutions

- Advanced Diagnostic Tools

Technicians utilize precision instruments to identify and correct imbalance issues with high accuracy. - Minimal Downtime

Onsite services eliminate the need to transport heavy equipment, drastically reducing downtime. - Cost Efficiency

In the long term, onsite balancing is more cost-effective since it eliminates the need for traveling and prolonged periods of idleness.

Advantages of Onsite Balancing for Turbocharger Maintenance

Enhanced Operational Efficiency

Balancing turbochargers onsite restores their optimal performance, ensuring engines operate at maximum efficiency.

Reduced Wear and Prolonged Lifespan

Onsite balancing mitigates stress on bearings and other components, prolonging the service life of turbochargers and reducing maintenance frequency.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

Customizable Solutions

Each turbocharger is unique, and onsite solutions allow tailored adjustments that meet specific operational requirements.

The Process of Onsite Balancing

Step 1: Preliminary Assessment

Technicians conduct a thorough evaluation of the turbocharger, analyzing vibration levels and identifying imbalances.

Step 2: Diagnosis and Planning

To identify the cause of the imbalance, exact measurements are made using sophisticated instruments like vibration analyzers and laser alignment systems.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Step 3: Correction

Weights are strategically added or removed from the rotating assembly to achieve perfect balance. This process is repeated and fine-tuned until vibration levels are within acceptable limits.

Step 4: Final Testing and Validation

After balancing, technicians perform rigorous testing to ensure the turbocharger operates efficiently without excessive vibration.

Industries Benefiting from Onsite Balancing

Automotive Sector

Turbochargers in commercial and passenger vehicles require regular maintenance for peak performance. Onsite balancing ensures minimal disruption to vehicle operations.

Marine Industry

Ships rely heavily on turbocharged engines for propulsion. Onsite balancing allows vessels to maintain continuous operations while undergoing maintenance.

Power Generation

In power plants, turbochargers are integral to the performance of gas turbines. Onsite balancing minimizes the downtime of these critical assets.

Oil and Gas

Turbocharged engines are prevalent in drilling and extraction operations. Onsite balancing solution

helps maintain efficiency and reliability in these demanding environments.

Technological Innovations in Onsite Balancing

Real-Time Monitoring

Advanced sensors and monitoring systems enable technicians to track performance metrics during the balancing process.

Portable Equipment

Compact and mobile balancing equipment makes it easier to perform services in remote or challenging locations.

Data-Driven Adjustments

Using precise analytics, technicians can make informed decisions to achieve optimal balance efficiently.

The Future of Turbocharger Maintenance with Onsite Balancing

As industries become more reliant on efficient and reliable machinery, the demand for onsite balancing engineering solutions will continue to rise. Innovations in diagnostic tools, coupled with a growing emphasis on minimizing operational disruptio