Acetyl Chloride Manufacturing Plant Project Report 2024: Analyzing Market Trends and Cost

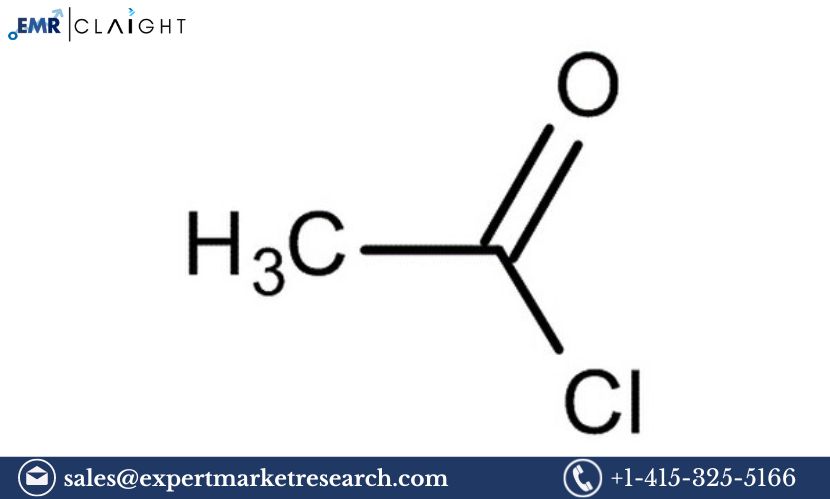

In today’s ever-evolving industrial landscape, the chemical sector plays a vital role in producing essential compounds used in everyday products. One such compound is acetyl chloride, a highly reactive and versatile chemical. It is used in numerous industries, including pharmaceuticals, agrochemicals, and textiles, due to its role in producing a variety of organic compounds. For businesses and entrepreneurs interested in the chemical manufacturing sector, an Acetyl Chloride Manufacturing Plant Project Report offers a detailed roadmap for setting up and operating a facility dedicated to producing this essential chemical.

In this article, we will explore the various aspects covered in an acetyl chloride manufacturing plant project report. This includes understanding the market demand, plant setup requirements, production processes, environmental regulations, and much more. By the end, you’ll have a clear picture of what’s involved in establishing an acetyl chloride manufacturing plant, and we’ll answer some frequently asked questions to clarify common doubts about this venture.

Understanding the Project Report

An Acetyl Chloride Manufacturing Plant Project Report is a vital document that provides comprehensive information on all the elements involved in setting up and running a manufacturing unit. It offers a step-by-step guide for entrepreneurs, investors, and stakeholders, ensuring they understand the economic, operational, and technical aspects of the business. Typically, this report includes:

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

- Market Analysis: Insight into the current demand for acetyl chloride in various sectors and projected growth trends. This helps potential investors assess the profitability and demand in the market, ensuring their venture will meet current industry needs.

- Feasibility Studies: Evaluates whether setting up an acetyl chloride manufacturing plant is a viable investment based on location, available resources, and market conditions. This section helps determine if the project is financially and technically feasible.

- Technical Requirements: Covers essential aspects of production, including machinery, raw materials, labor, and infrastructure. It also outlines the manufacturing process without delving into chemical reactions or complex technicalities.

- Regulatory Compliance: Ensures the plant adheres to environmental and safety regulations, an essential aspect in today’s environmentally conscious world. The report highlights the necessary permits, certifications, and protocols for safe operation.

Get a Free Sample Report with Table of Contents @

Market Overview and Demand

One of the first sections of an acetyl chloride project report deals with market analysis. Acetyl chloride has a significant demand due to its extensive use in industries like pharmaceuticals, where it is essential in producing active ingredients, and agrochemicals, where it is used to make herbicides and pesticides.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

The report typically evaluates:

- Current Demand: The role of acetyl chloride in various industries ensures steady demand for this chemical. Pharmaceuticals and agrochemicals are among the largest consumers, but there’s also substantial demand from the dyes and plastics industries.

- Future Growth: As industries like pharmaceuticals and agrochemicals continue to expand, so too does the demand for acetyl chloride. For instance, the increasing demand for medicines and agricultural solutions is directly tied to the need for acetyl chloride.

- Geographical Analysis: The report often breaks down demand across different regions, giving investors insight into where their production might best serve growing markets.

Plant Setup and Infrastructure

Setting up an acetyl chloride manufacturing plant involves several key components that must be considered to ensure smooth operations. The project report provides an in-depth look at these aspects, helping entrepreneurs and businesses plan their investments wisely.

Location and Land Requirements

The choice of location is crucial for any manufacturing plant. Proximity to raw material suppliers, availability of labor, and ease of transportation are just a few of the factors that influence location decisions. The report also outlines the ideal land area required for setting up the facility, considering factors like storage, safety protocols, and future expansion possibilities.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Machinery and Equipment

The machinery required for acetyl chloride production is an essential part of the project report. While the document doesn’t delve into specific technical processes, it does offer an overview of the types of equipment needed, including reactors, distillation units, and storage facilities. It highlights the need for machinery that is both cost-effective and efficient, ensuring maximum productivity while maintaining product quality.

Labor and Workforce

A well-trained and skilled workforce is another vital element for operating a manufacturing plant. The project report includes a labor assessment, detailing the number of workers needed for different functions, including plant operations, maintenance, and quality control. It also outlines necessary training programs to ensure that the workforce is equipped with the skills to handle production processes safely and efficiently.

Safety and Environmental Compliance

Given that acetyl chloride is a reactive chemical, safety is paramount in its production. The project report emphasizes the importance of adhering to strict safety protocols to protect workers and the environment. Compliance with local and international environmental regulations is crucial, and the report outlines the necessary steps to obtain permits and certifications, as well as methods for waste management and emissions control.

Financial Analysis and Cost Estimates

While this article avoids numerical details, the project report typically includes an extensive financial analysis to help investors understand the cost structure and revenue potential of the plant. The financial analysis usually includes capital investment requirements, operating expenses, and projected returns. It also covers:

- Raw Material Costs: A breakdown of the expenses involved in sourcing the raw materials required for acetyl chloride production.

- Operational Costs: This includes labor, utilities, transportation, and other recurring expenses necessary for plant operation.

- Revenue Projections: Estimates of potential revenue based on production capacity and market demand.

- Profitability Analysis: A study of the projected profits over time, taking into account factors like market growth, competition, and price fluctuations.

Risk Assessment and Management

Every manufacturing venture carries certain risks, and the acetyl chloride manufacturing business is no exception. The project report highlights potential risks associated with the plant, such as fluctuations in raw material prices, changes in environmental regulations, and safety hazards. It also provides risk mitigation strategies to help businesses prepare for and manage these challenges.

Some of the key risk factors covered include:

- Market Risk: The risk that demand for acetyl chloride may decline due to changing industry needs or technological advancements.

- Operational Risk: Risks related to plant downtime, machinery breakdowns, and labor shortages.

- Regulatory Risk: Potential changes in environmental or safety regulations that could impact plant operations or increase compliance costs.

Opportunities for Growth

Despite the risks, the acetyl chloride manufacturing industry presents several opportunities for growth, which the project report explores in detail. For instance, increasing demand for eco-friendly agrochemicals and pharmaceutical products is driving growth in the acetyl chloride market. The report also highlights opportunities for export, as the demand for acetyl chloride is growing in regions with expanding industrial sectors.

Businesses can also explore vertical integration, where they produce not just acetyl chloride but also other related chemicals or intermediates, creating a broader product portfolio and tapping into new market segments.

FAQs

1. What are the key components of an acetyl chloride manufacturing plant project report?

The report covers a wide range of topics, including market analysis, feasibility studies, plant setup, technical requirements, safety and environmental compliance, financial analysis, and risk management. It serves as a comprehensive guide for entrepreneurs looking to set up a manufacturing unit.

2. How important is market analysis in the project report?

Market analysis is crucial as it helps investors understand the current and future demand for acetyl chloride, ensuring that there is a viable market for their product. It also provides insights into regional demand, allowing businesses to make informed decisions about where to set up their plant.

3. What are the safety considerations when manufacturing acetyl chloride?

Given the reactive nature of acetyl chloride, strict safety measures must be implemented. This includes using proper personal protective equipment (PPE), maintaining rigorous safety protocols in the plant, and ensuring compliance with environmental regulations to minimize emissions and waste.

4. What are the potential risks in acetyl chloride manufacturing?

The risks include fluctuations in raw material prices, changes in environmental regulations, safety hazards due to the chemical’s reactivity, and potential declines in market demand. The project report typically includes risk mitigation strategies to address these challenges.

5. How can businesses ensure environmental compliance?

The project report outlines the necessary steps for environmental compliance, including obtaining permits, adhering to waste management protocols, and implementing emissions control measures. Businesses must stay up-to-date with local and international regulations to avoid penalties and maintain safe operations.

6. Is an acetyl chloride manufacturing plant profitable?

While profitability depends on various factors such as market demand, production capacity, and operational efficiency, the acetyl chloride industry shows promising growth. The project report typically includes profitability projections, helping investors gauge the potential return on investment.

Related Reports

https://www.expertmarketresearch.com/reports/sauces-market

https://www.expertmarketresearch.com/reports/fraud-detection-and-prevention-market

https://www.expertmarketresearch.com/reports/spain-residential-real-estate-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au