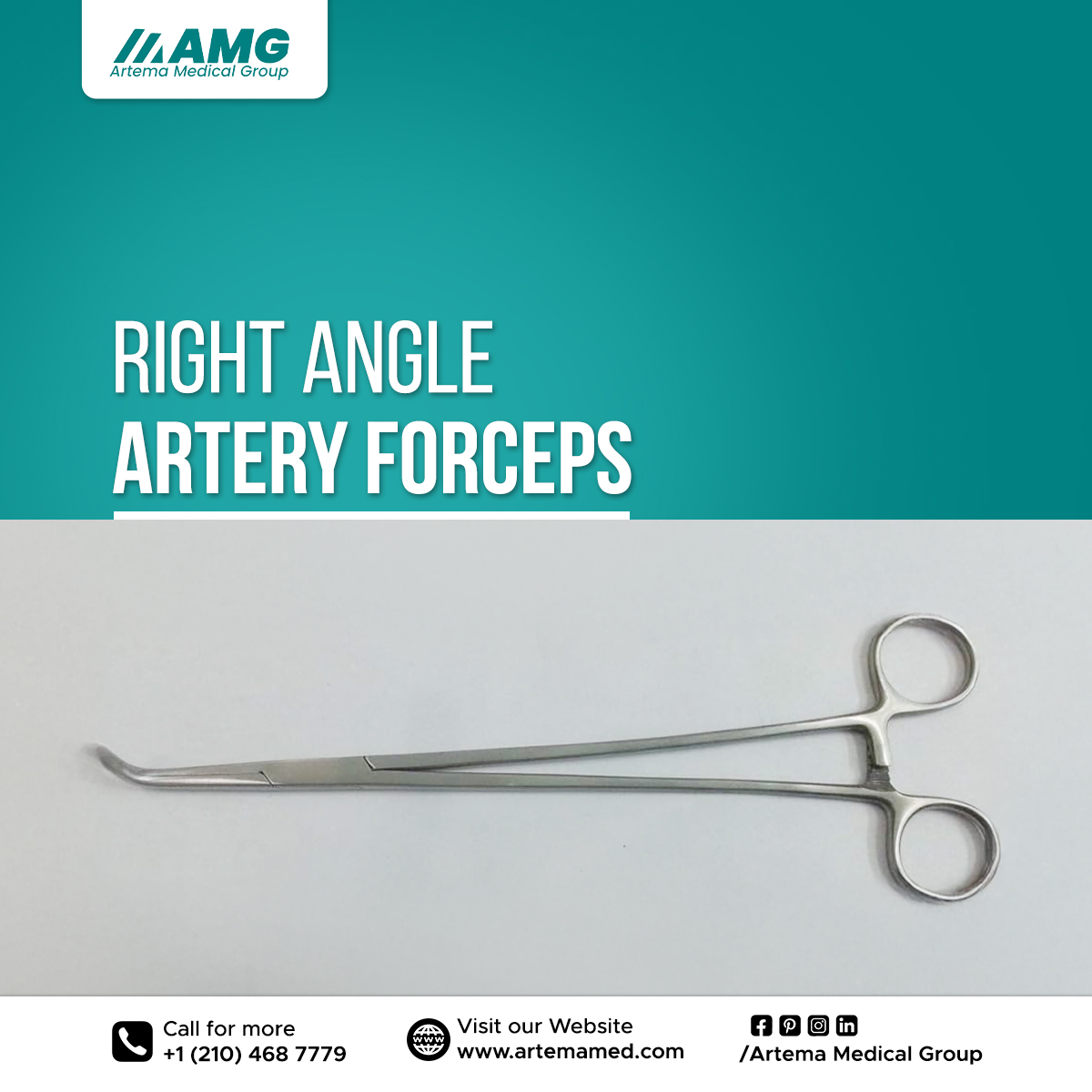

Right Angle Artery Forceps: Usage and Manufacturing in Hospitals

Right angle artery forceps are essential surgical tools used in hospitals worldwide. They play a critical role in various medical procedures, particularly in clamping blood vessels, dissecting tissues, and guiding sutures. These instruments are not only valued for their functionality but also for the quality and precision achieved through expert manufacturing. With a design focused on performance and durability, right angle artery forceps are a must-have in every surgical setting.

Let’s explore how these forceps are used in hospitals and how their manufacturing process ensures safety, reliability, and long-lasting performance.

Clinical Usage in Hospitals

In hospital environments, right angle artery forceps are used extensively during surgeries. Their unique 90-degree angled tip makes them ideal for reaching deep or narrow areas where straight forceps cannot function effectively. This design enables surgeons to work with confidence and control during complex operations.

Do you want to visit Char Dham? Char Dham Travel Agent is the best place to plan your Char Dham tour. You can book the tour from here.

Clamping Blood Vessels

The primary use of right angle artery forceps is clamping arteries or veins to control bleeding. During procedures, surgeons apply the forceps to block blood flow temporarily while tying off or cauterizing the vessel. The secure grip ensures minimal blood loss and keeps the surgical area clear for better visibility.

Deep Tissue Access

In abdominal, thoracic, and pelvic surgeries, surgeons often need to access deep tissue structures. The angled design of these forceps helps reach vessels or tissues located behind organs or bones without damaging surrounding structures. This feature reduces the need for additional incisions, which leads to faster healing.

Suture Guidance and Dissection

Hospitals rely on right angle artery forceps for guiding sutures around vessels and assisting in blunt dissection. The fine jaws gently separate tissue layers without causing trauma. This is particularly useful in vascular and neurosurgical procedures where delicate handling is crucial.

Would you like to visit Indiar? A tour operator in India is the best place to plan your tour. You can book a tour from here.

Use in Specialized Departments

These forceps are not limited to general surgery. They are also used in ENT, dental, orthopedic, and cardiovascular departments. Whether it’s removing foreign bodies, assisting in laparoscopic surgeries, or handling delicate tissues, right angle artery forceps are present in almost every surgical tray.

Manufacturing Process of Right Angle Artery Forceps

The manufacturing of right angle artery forceps involves advanced techniques, strict quality control, and precision engineering. Each stage of production is designed to ensure that the final product meets the high standards required in medical environments.

Material Selection

High-grade surgical stainless steel is the most commonly used material. This steel is chosen for its corrosion resistance, durability, and ability to maintain sharpness. It is biocompatible, meaning it is safe for use inside the human body and can be sterilized repeatedly without degradation.

Would you like to visit Haridwar? Travel agents in Haridwar are the best place to plan your trip. You can book your tour right here.

Forging and Shaping

The manufacturing process begins with forging the steel into the desired shape. Precision tools and molds help form the right angle tip and handles. The forging process strengthens the metal, ensuring it can withstand pressure without bending or breaking.

Grinding and Finishing

Once the basic shape is formed, the forceps undergo grinding to smooth out any rough edges and perfect the jaw alignment. Serrations are added to the inner surfaces of the jaws to provide a secure grip on tissues and vessels. A polished or satin finish is then applied, depending on the model. This not only enhances appearance but also reduces glare during surgeries.

Assembly and Locking Mechanism

The ratchet lock mechanism is carefully installed to allow surgeons to adjust and lock the forceps at various levels of tension. This locking system is tested for reliability and smooth operation. Proper alignment is crucial to ensure that the forceps close and lock evenly every time.

Sterilization and Testing

Before being packed and shipped, each instrument is cleaned, sterilized, and tested for performance. Manufacturers follow international standards such as ISO and CE to ensure the instruments are safe and effective. Forceps are tested for grip strength, jaw alignment, and smooth locking action.

Packaging and Delivery

After passing all quality checks, the forceps are packed in sterile conditions or in bulk for hospitals that prefer on-site sterilization. Proper labeling and documentation are included to comply with hospital procurement and inventory standards.

Trusted by Hospitals Worldwide

Hospitals demand instruments that are precise, reliable, and durable. Right angle artery forceps, when manufactured with care and expertise, provide exactly that. Surgeons trust them during critical moments, and their consistent performance supports successful outcomes.

Manufacturers who specialize in surgical tools ensure that each forceps not only meets medical needs but also exceeds expectations in quality and handling. The collaboration between skilled manufacturers and medical professionals creates instruments that improve surgical safety and efficiency.

Conclusion

Right-angle artery forceps are a vital part of hospital surgical instruments. Their ability to clamp, dissect, and guide with precision makes them essential for various procedures. The manufacturing process—from material selection to final testing—ensures that these forceps are durable, sterile, and safe for patient care.

Hospitals and medical professionals looking for trusted surgical tools can rely on Artema Med, a reputable manufacturer delivering premium-quality right angle artery forceps and a complete range of surgical instruments worldwide.